Safe Packaging with a Strapping Machine.

To prevent accidents and damage to goods, strapping of load units on carriers is an essential part of load securing in the logistics industry. This securing process can be facilitated and simplified by using strapping machines. The following article outlines the various options and the importance of load securing, as well as explaining how a strapping machine works.

What strapping options are available? From manual strapping to strapping machines

Manual Strapping

One option is manual strapping. In this method, the pallet is strapped by hand — often referred to as the “broomstick method.” The strapping band is attached to a stick, pushed manually under the pallet, and guided around it. The strap, which is fed via a dispenser cart, is then tensioned and sealed using either a tensioner or a battery-powered sealing head. This ensures that the products on the pallet are securely strapped.

Lance Device

Another strapping option is a mobile pallet strapping machine, also known as a lance device. This machine uses a lance to feed the strapping band under the pallet. Similar to the manual method, the band is picked up on the opposite side of the pallet and guided over the top for sealing. While this provides a more efficient solution than manual strapping, it does not offer an ergonomic working process.

Semi-Automatic Strapping Machine

Manual strapping tools were long considered the standard method for securing load units. However, they often require significant physical effort and can lead to inefficient results. Semi-automatic strapping machines such as ErgoStrap offer a more convenient alternative by supporting the operator during the strapping process while reducing physical strain. ErgoStrap has established itself as the global leader in ergonomic and mobile strapping systems within the packaging industry. Similar to lance devices, ErgoStrap’s strapping systems use a chain that travels under the pallet. However, unlike other methods, the operator does not need to retrieve the strap on the opposite side. Instead, the strap travels around the pallet via the chain lance and can be caught and returned by the user. The sealing process is then performed with the sealing head, which is attached to the machine via the integrated tool-lift. This allows the strap to be welded securely and completes the load unit securing process ergonomically, safely, and efficiently.

Significance of load unit securing

Securing goods using pallet strapping machines plays a vital role in the logistics industry. It ensures safety by preventing the load from shifting, tipping over, or falling during transport. Properly secured load units significantly reduce the risk of accidents, property damage, and personal injury. In addition, securing the goods correctly helps prevent damage during transit, ensuring better protection for the cargo.

Goods that arrive at the customer’s location in perfect condition reinforce quality standards and enhance customer satisfaction.

Moreover, legal regulations and industry guidelines mandate proper securing of load units and transported goods.

What kind of strapping machine does ErgoStrap offer?

- Fully integrated sealing head on a tool-lift, which can be quickly and conveniently removed

- Strap brake relief system reduces the roll brake pressure by up to 80% using a foot pedal, making manual band pulling significantly easier

- Line laser simplifies precise positioning at the pallet

- Simple and intuitive operation – optionally supported by an on-site introduction course for your employees

- Electronically controlled drive and joystick operation

- Integrated lithium battery allows for up to 1,400 strapping cycles per charge

- ErgoStrap is twice as fast as manual strapping

- All models of the X-pert Line are equipped with a Siemens industrial touchscreen, which allows the pallet width to be adjusted in 4" increments easily

Ergonomic

ErgoStrap – Award-Winning System

A product that supports the spine and relieves the user must meet strict medical standards. The “Campaign for Healthier Backs” (Aktion Gesunder Rücken – AGR) awards its seal of approval only to products that are demonstrably designed to promote back health and have been reviewed by an independent panel of experts. The AGR seal provides consumers with clear guidance when choosing back-friendly products. All ErgoStrap systems are certified with the AGR seal, representing ergonomics and health.

Easy

ErgoStrap enables quick training of employees thanks to its intuitive and user-friendly operation. Physically demanding work becomes enjoyable again with ErgoStrap.

Efficient

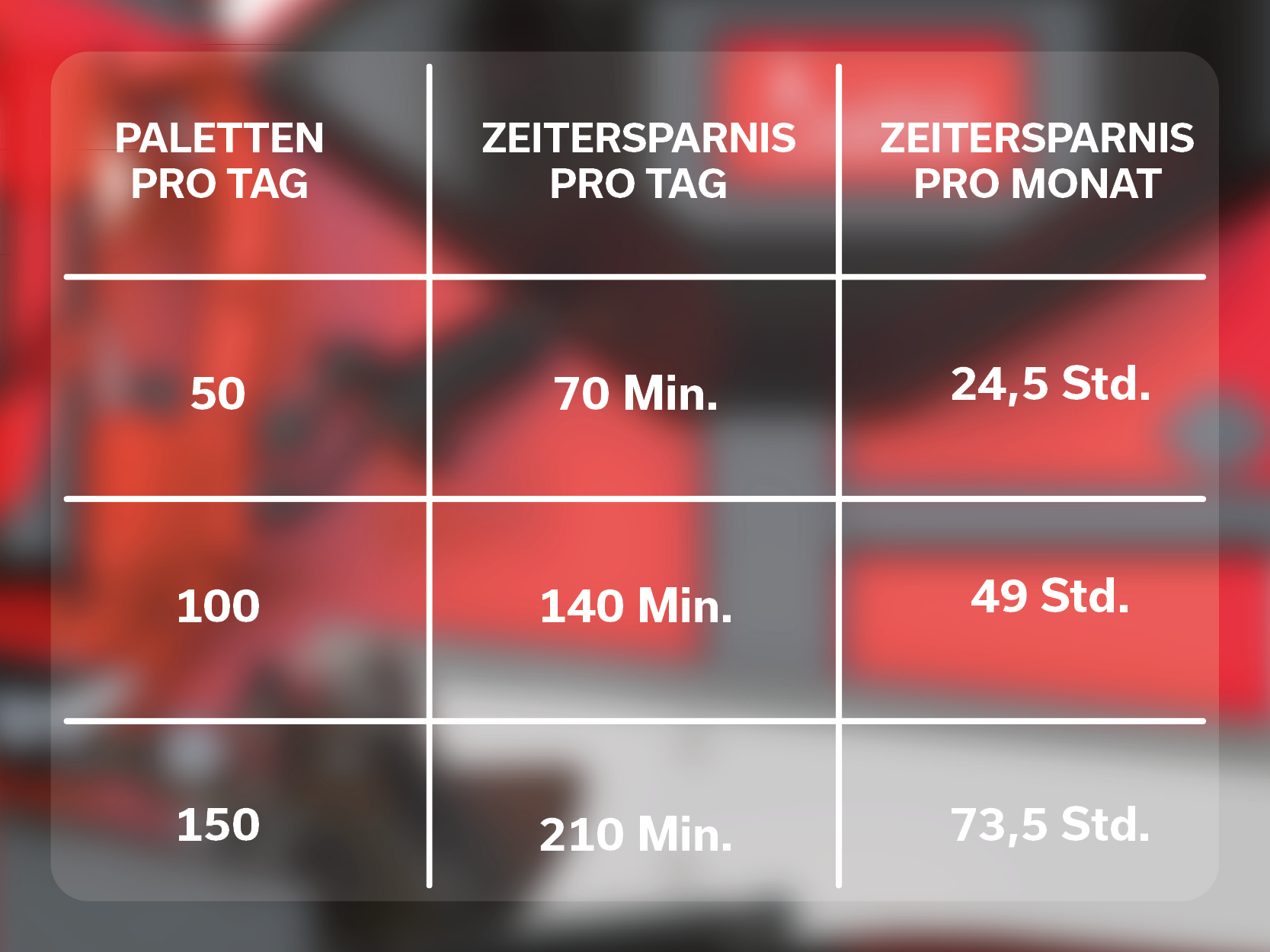

With ErgoStrap, pallets can be strapped twice as fast. A double strapping of a pallet by professionals takes about two minutes by hand. ErgoStrap does it in less than 40 seconds. This results in significant time savings. Here’s a sample calculation:

What are the advantages of the ErgoStrap strapping machine?

Benefits for Employers:

- Increased employee safety: Bending down and disappearing behind the pallet are eliminated, significantly reducing the risk of accidents involving forklift traffic

- Improved load securing quality: Goods remain undamaged and in excellent condition

- Greater employee satisfaction and motivation: Physically demanding work becomes enjoyable again with ErgoStrap

- Fewer employee absences: Fewer sick days mean more efficient processes

- Twice as fast strapping process: Complete twice the work in the same time, saving costs and optimizing workflows

Employees are enthusiastic:

- No more bending: At 100 strappings per day, that’s 50,000 bending movements a year—ErgoStrap eliminates them and supports long-term health!

- No need to walk around the pallet: With manual strapping, 100 strappings per day mean 25,000 trips around the pallet per year—with ErgoStrap, that number drops to zero

- More comfort during pallet strapping

- Work more efficiently: No more bending or walking around pallets significantly reduces time and effort

- Flexible working through mobile usability: Thanks to its semi-automatic design

- No additional tools needed: No strapping cart or separate sealing device required—ErgoPack includes everything in one machine

Employees report

TestimonialsWhat kind of strapping machine does ErgoStrap offer?

Are you interested in an ErgoStrap strapping system but unsure whether it's the right fit for your application? No problem! We’ll gladly visit your facility so you can experience the ErgoStrap system live and on site.

Our team will demonstrate the ErgoStrap system in your familiar working environment and directly on your pallets. This way, you’ll get a hands-on impression of how the ErgoStrap strapping machine works and the benefits it offers. Afterwards, you’ll receive a customized quote tailored specifically to your needs.

Feel free to contact us – we look forward to presenting the ErgoStrap system to you in person and answering any questions you may have!